Overview

V8950 - Variable Chamber Round Baler

The McHale V8950 is a semi-automatic variable chamber baler which is fitted with a 15 knife chopper unit and heavy-duty rotor. It is equipped with a double drive system which allows the machine to operate in the toughest of conditions. The double drive system aids belt rotation and bale formation. The machine comes with centralised grease blocks as standard. Automatic greasing is available as an option on all V8950 machines. Net and bale density can be adjusted from the cab through the Expert Plus control console. The machine is fitted with 500/50-22.5 tyres as standard.

Features include:

- 2.1m High-Intake Pick-Up with Galvanised Bands

- 15 Knife Heavy Duty Rotor

- 15 Knife Chopper Unit

- Double Drive System

- Expert Plus Control System

- Centralised Greasing Blocks

- Optional Camless Pick-Up

Pick Up

McHale have developed various types of pick-ups. After extensive testing, McHale decided it would offer customers the choice of 2 pick-up options depending on their conditions:

Cam Pick-Up - Optional indent order only

- As standard, a cam operated 2.1 m high-intake galvanised pick-up ensures excellent ground cleaning in all types of crop. The cam pick-up runs on a cam track that is fitted with double raced cam bearings to stand up to the most testing of conditions.

- All pick-ups across the McHale variable chamber baler range are fitted with 5 tine bars for excellent delivery of crop to the bale chamber. The 2.1 metre galvanised pick-up will lift even the shortest of crop. A side inspection port allows the operator to quickly check and change the cam bearings.

Camless Pick-Up

- A 2.1 m camless pick-up is available as an option on all machines in the variable chamber baler range. Six tine bars are fitted to all McHale camless pick-ups to provide excellent ground cleaning and fast delivery of crop to the chamber. The new camless pick-up has been designed for increased output, with that in mind the cam-track free pick-up is more reliable, consists of less moving parts and is maintenance free.

All McHale pick-ups come with a number of standard features that include:

Heavy Duty Pick-up

All McHale pick-ups feature heavy-duty tine bar supports to ensure long service life. A vital part of the pick-up is the tine, McHale have developed a pick-up tine designed to lift even the shortest of crop.

Efficient Crop Flow Delivery

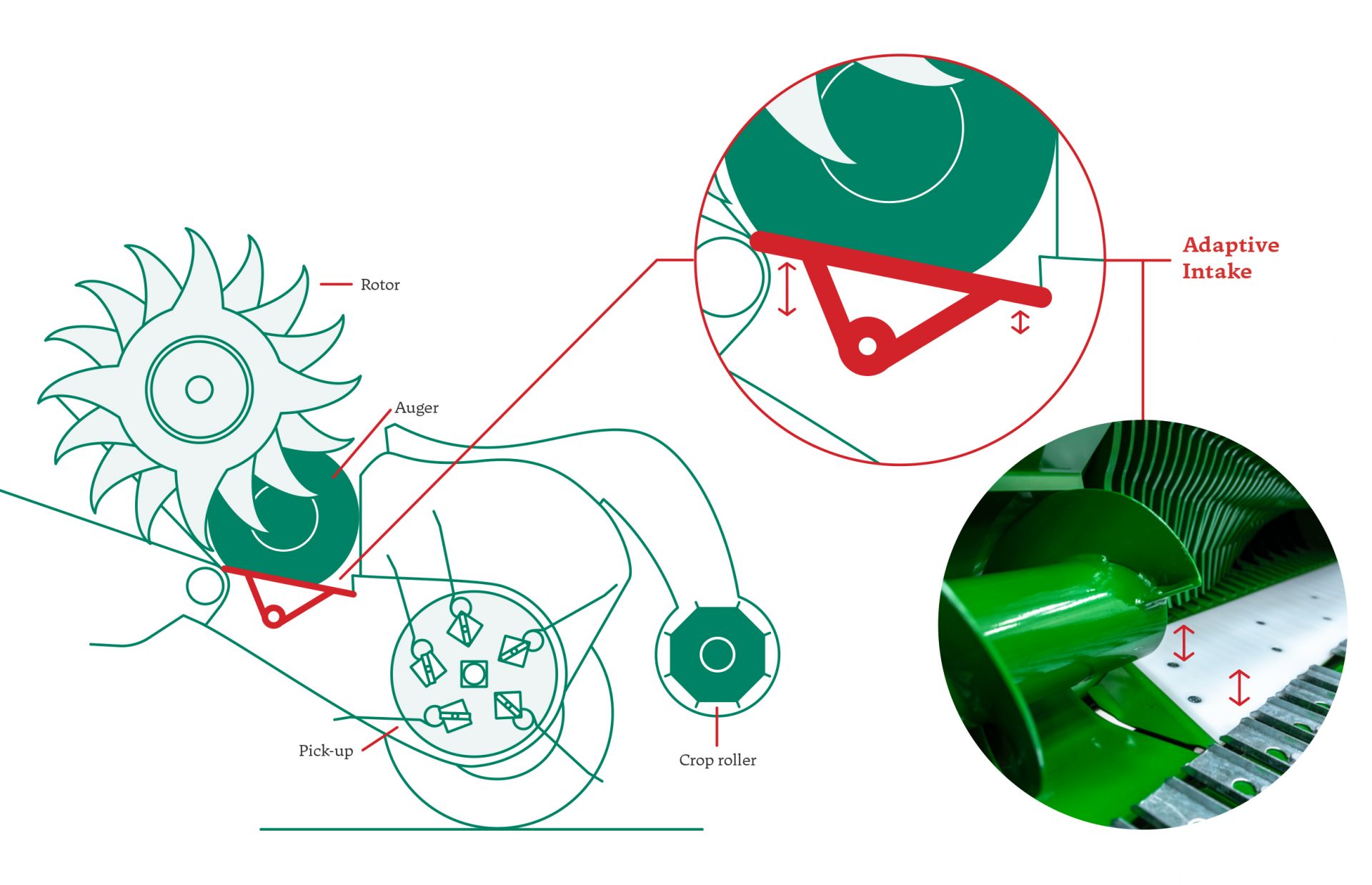

The specially designed McHale pick-up is positioned close to the rotor to improve delivery of the crop through the rotor to the bale chamber. Large diameter lateral feed augers help direct crop to the bale chamber ensuring a consistent and even crop flow for producing high density bales.

Adaptive Intake

Over the course of a baling season, machines have to work with different volumes of crop. McHale have designed an adaptive intake which allows the intake area to automatically adjust for light and heavy crops. This avoids peak loads and results in higher daily throughput regardless of working conditions.

Rotor

The V8950 is fitted with a 15 Knife Chopper Rotor

The feed rotor or chopping unit boasts a heavy-duty rotor and comb.

The flights are welded on both sides for superior strength and on the drive side the rotor is fitted with a double row bearing with a long service life.

The star shaped feed rotors ensure a high capacity flow of grass into the bale chamber. The flights on the rotors are laid out in a spiral formation to achieve consistent crop flow.

As crop enters the rotor, rotating flights feed the crop to the bale chamber. The flights on the rotor ensure high output, while the star layout reduces the load peaks as the machines work in heavy swaths.

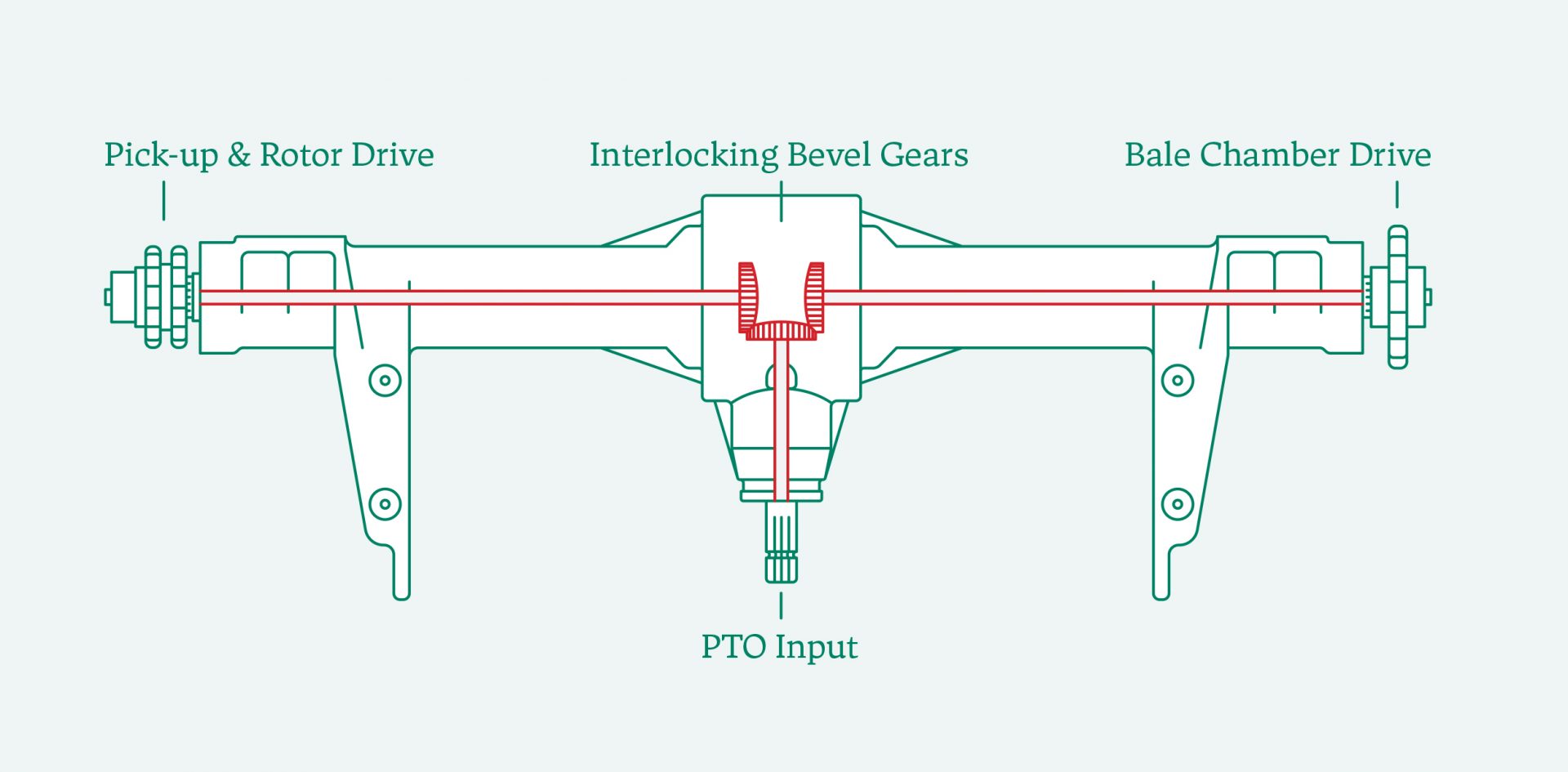

Gear Box

A Split Drive Gearbox is fitted to all machines in the McHale variable chamber baler range. The gearbox design ensures that power is evenly distributed to both sides of the baler.

The belt(s) in the bale chamber are driven from the left hand side of the machine, and the pickup and chopper unit are driven from the right hand side of the machine.

This system ensures direct, short transfer paths, leading to optimal power distribution

Drop Floor

For over a decade, all machines in the variable chamber baler range have been fitted with the McHale Drop Floor Unblocking System , a feature which operators have come to love for it’s simplicity of use and effective unblocking cycle.

As baling conditions are not always ideal, uneven swaths can occur which can lead to blockages. The McHale variable chamber baler range is fitted with a drop floor unblocking system, which means blockages can be fed through in three simple steps.

Drop the Floor

- Should a blockage occur, the sound of the slip clutch alerts the operator, who can hydraulically lower the floor from the tractor cab.

Re-engage the PTO

- This widens the feed channel and on re-engaging the PTO, the blockage can be fed through.

Reset the Floor

- The floor can then be reset to its original position and baling can resume.

Control Console

The McHale V8950 is fitted with an Expert Plus control console, which has a large graphic display. The Expert Plus console, also gives the operator the choice of selecting a soft or hard bale core, depending on the customers feed out requirements. The control console can also store ten bale count totals so the operator can record ten different counts that may be associated with different fields or different customers.

From the control console in the tractor cab the operator can adjust the following;

- Core Size & Bale Size

- Core Density & Bale Density

- Revolutions of Net Being Applied

The McHale Expert Plus Control Console also features:

- Knife Display

- Door Position Display

- Pre-Net Bale Formation Alert

- Net Usage (Metres)

- Bale Size Setting

- Bale Size Display

- Drop Floor Display

- Lube Count

- Lube Alarm

- Net Layers

- Bale Density

- Bale Shape Indicator

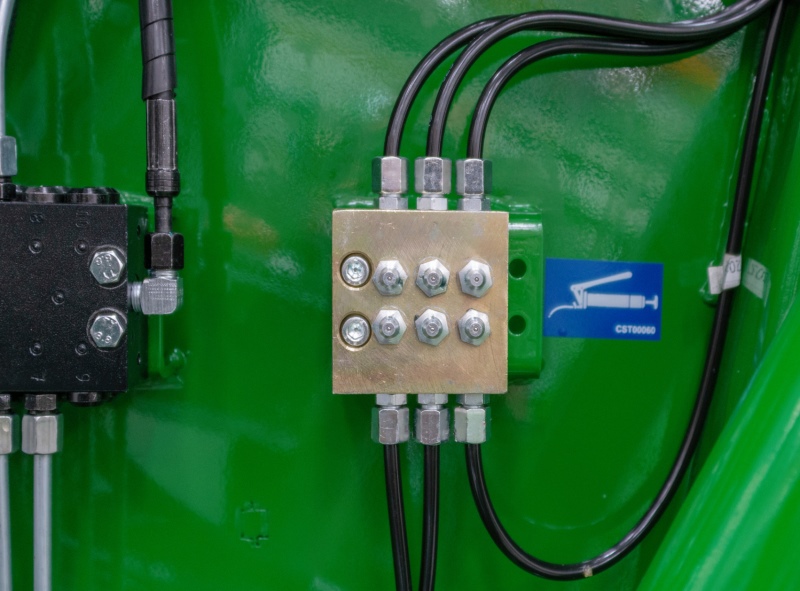

Lubrication

The McHale variable chamber baler range of balers are all fitted with a continuous oiling system. Once the PTO is engaged, the continuous oiling system constantly lubricates the chains to ensure a long lifetime.

The continuous oiling system on the machine is driven off the gearbox and delivers oil to the following chains:

- Chamber Drive - Side Chains

- Rotor – Drive Chain

- Pick-Up – Drive Chains

- Pick-Up – Cam Track

- Pick-Up – Drive Gears

Automatic Greasing

- A pressurised system delivers a measured amount of grease around the baler every time a bale is ejected from the bale chamber. Automatic greasing saves time as it reduces the amount of manual greasing to be done by the operator. A lube alarm sounds after 300 bales to inform the operator to refill the grease.

Specifications

V8950

|

Weight & Dimensions

|

|

|

Width

|

2.558m / 2.62m* depending on tyre size

|

|

Length

|

5.1m

|

|

Weight

|

4,850kg

|

|

Height

|

3.12m

|

|

Working width

|

2.10m

|

|

Pick Up

|

|

|

Tine Bars

|

5

|

|

Tine Spacing

|

70mm

|

|

Short Crop Guard

|

Optional

|

|

Crop Roller

|

Standard

|

|

Pick Up Guide Wheels (pneumatic)

|

Standard

|

|

Chopper Unit

|

|

|

Number of Knives

|

15

|

|

Theoretical Chop Lenght

|

65mm

|

|

Knife Protection

|

Hydraulic |

|

Knife Deactivation

|

Hydraulic from Cab

|

|

Unblocking System

|

Drop Floor

|

|

Bale Chamber

|

|

|

Diameter

|

0.6m to 1.9m

|

|

Width

|

1.23m

|

|

Bale Chamber Feed

|

15 Knife Chopper Feed Rotor

|

|

Number of Belts

|

3

|

|

Net Wrap

|

|

|

Control

|

Manual or Automatic

|

|

Net System

|

High Performance Netter

|

|

Net Roll Capacity

|

1+2 Storage

|

|

Net Adjustment

|

In Cab

|

|

Transmission

|

|

|

Gearbox

|

Split Drive

|

|

Main Drive Protection

|

Cam Clutch

|

|

Pick Up Protection

|

Slip Clutch

|

|

Chain Lubrication

|

Continuous

|

|

Bale Chamber

|

Double Drive

|

|

Control

|

|

|

Control System

|

Expert Plus

|

|

Operation

|

Semi Automatic

|

|

Density Adjustment

|

In Cab

|

| Bale Size Adjustment |

In Cab |

|

Inbuilt Camera

|

N/A

|

|

Other

|

|

|

Axle

|

8 Stud

|

|

Tyres Standard

|

500/50/22.5

|

|

Tyres Optional

|

560/45/22.5

|

|

Road Lights

|

Standard

|

|

Electronics

|

12 Volt DC -20 amp

|

|

Bale Kicker

|

Adjustable

|

|

Tractor

|

|

|

Minimum Hydraulic Flow

|

30 Litres / min at 180 bar

|

|

Hydraulic System

|

Open. Closed or Load Sensing

|

|

Minimum PTO Requirements

|

60kw (80hp)

|

Brochure

Images